Overall Solution Of Wind Power Plant

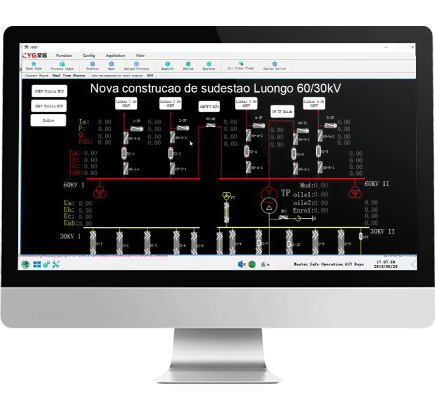

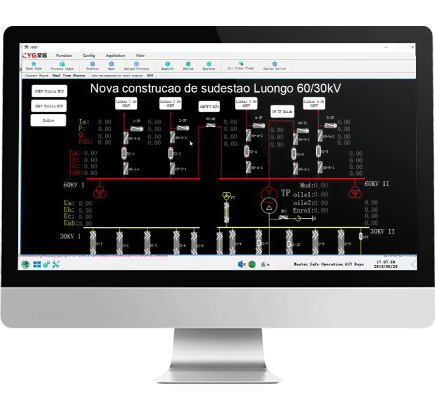

According to the requirements forwind power generation,CYG SUNRI provides solutions such as remote centralized control, integrated automation of substation, power forecasting, power control, video monitoring, and microcomputer inter-locking systemin case of mal-operation,to ensure smooth grid connection of windpower plant,improve safety management and economic benefits of windpower plant, and reduce the construction and investment risks.

(1) Land centralized wind power generation solution: It can meet the comprehensive monitoring, grid connection and dispatching requirements of windpower plants, and provide comprehensive real-time monitoring of wind turbines, anemometer tower, box transformer,step-up substation, and environmental monitoring system.

(2) Land distributed wind power generation solution: It has achieved the core objective of "unattended, attended with fewer persons and regional maintenance" of substations and plants, a visual monitoring platform withdual structure of C/S and B/S is provided, and centralized monitoring and management of multiple unattended stations is implemented.

(3) Offshore wind power generation solution:The system can provide remote monitoring and control of the equipment in the land metering station and the offshore step-up substation, and achieve various closed-loop control functions according to the requirements of the power grid operation mode.