PRS-7910 as a station communication manager, which collects, stores and

maps signals of relays, measurement units, control units and other IEDs

in the substation to higher-level systems such as control center (CC)

and distributed control system (DCS).

The PRS-7910 supports several protocols, such as IEC 61850, IEC

60870-5-101/104, IEC 60870-5-103, Modbus and DNP3.0. Data can be

transmitted to and received from analog channel, digital channel or

network connected to CC, DCS or other system. The direct transmission

mode and the device independent avoid any interaction or influence with

the substation SCADA (Supervisory Control And Data Acquisition) system.

Furthermore, the PRS-7910 can runs as a data acquisition and logic

treatment platform and provides various and flexible advanced function

extensions.

01

The database is compatible with data model IEC 61850 and IEC 103

Support of multiple models including primary/secondary equipment model, association model, primary schematic diagram model, etc.

Full modeling view and data information

Unified data acquisition and transmission.

02

Standard package for server: IEC 60870-5-101/104, DNP, Modbus

Standard package for client: IEC 60870-5-101/104, IEC 60870-5-103, DNP, Modbus

Advanced package: IEC 61850 server & client

Customized package: Other customized protocol

03

The data model transmission between substation and control center is realized by using the SCD file.

Support of most international standard protocols including IEC 60870-5-101/104, IEC 60870-5-103, DNP, IEC 61850, etc.

04

Highly integrated configuration functions

Full substation configuration support including project implementation, running, maintenance, analysis, diagnostic and debugging.

05

Up to 1024 IEDs

Up to 32 control centers

Database > 200,000 signals

06

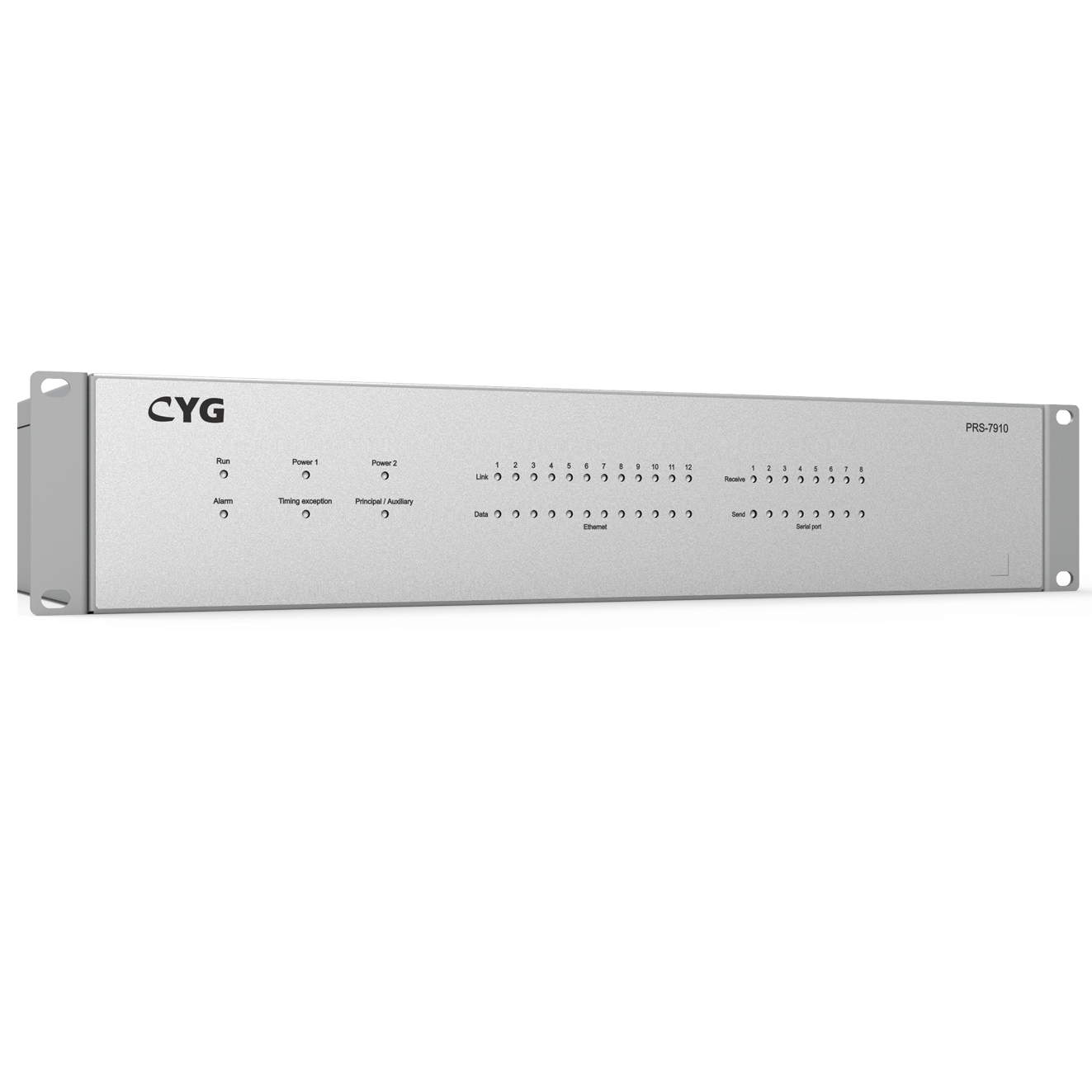

2U 19" small space occupationwith full feature and flexible configuration

07

Embedded history database

Optional capacity: 64 ~150 GB SLC SATA

Multiple data storage types including historical SOE records, operation reports, wave files, etc.

08

The response success rate from device to control centre > 99%

09

Internal SOE transmission delay <100ms

010

Dual power supply module is an option. The extra power supply module will be placed at the other side of the device rack and works independently.

011

Dual 1.60 GHz CPUs, 2GB RAM, optional 64 ~150 GB SLC SATA SSD storage memory for historical data

Capable for data management and communication of the SAS for whole substation or power plant

CPU usage < 25% during normal service; CPU usage < 50% during massive data treatment Communication ports:

The 2U 19" chassis supports up to 8 Ethernet ports and 8 serial ports

Non-rotating storage is adopted to avoid vibration

A fully closed chassis with a complete panel

Completely separated spaces for electronic and electrical systems

Designed with anti-interference measures to enhance the device EMC.

W×D×H:425mm×280mm×88.1mm